Welcome to Shandong Hongfan Power Technology Co.,Ltd

Injector body Корпус инжектора L250-52-201 zichai L250 diesel marine engine

Essential Engine Components for ZICHAI L250 OVERHAUL

Introduction

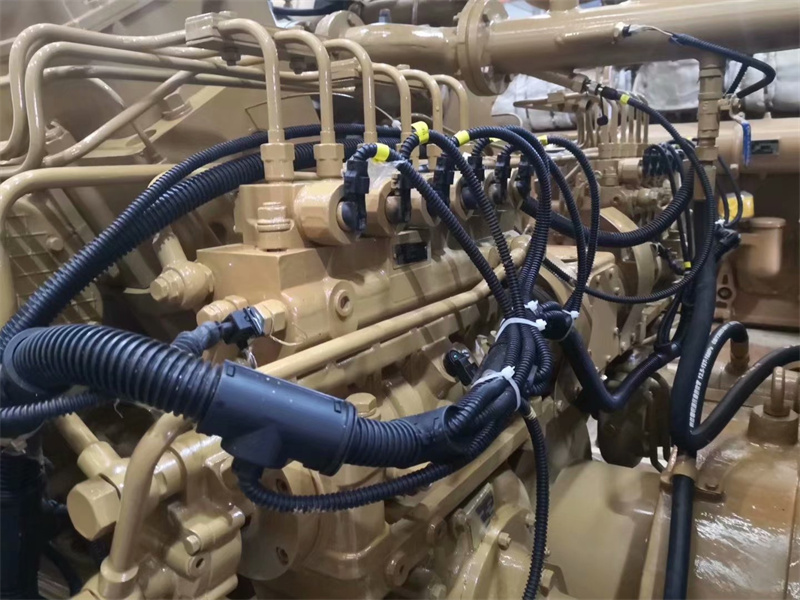

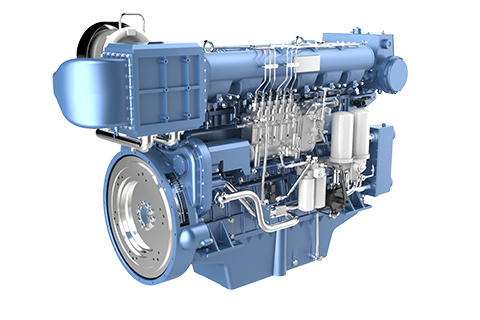

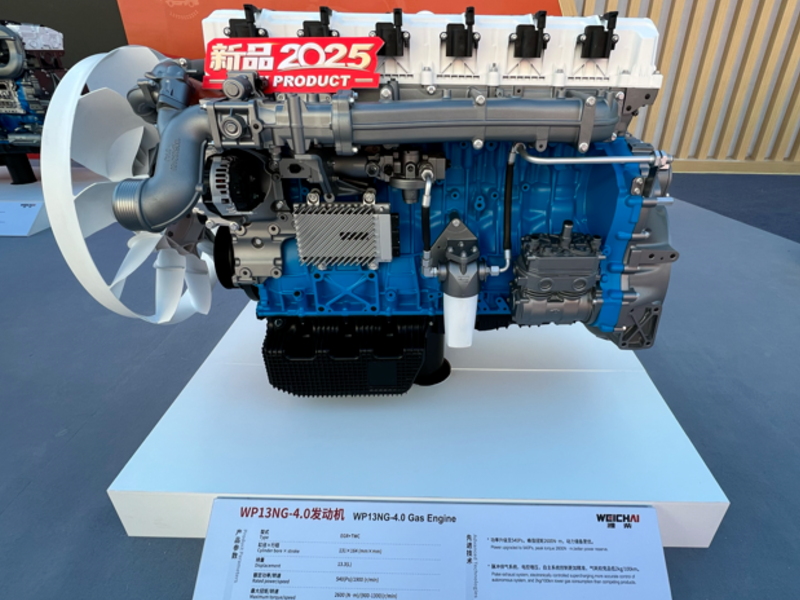

The ZICHAI L250 series engine is engineered for high efficiency and durability, ideal for marine, industrial, and power generation applications. Equipped with premium components like injectors, camshafts, intake/exhaust valves, and high-pressure fuel pipes, the L250 delivers exceptional performance and extended lifespan. Whether operating under heavy loads in harsh conditions or requiring long-term stability, the ZICHAI L250 meets high standards, making it the perfect choice for those seeking a dependable, high-performance engine.

1. Injector Components: Precision in Fuel Delivery

·

Injector Body (L250-52-201): The injector body is a vital part of the fuel injection system, responsible for delivering fuel into the combustion chamber with precision. Constructed for durability, this component ensures efficient fuel atomization, contributing to cleaner combustion and reduced emissions.

·

·

Injector Needle Valve Body (L250-52-102 / L250-52-100D): The needle valve body controls the amount of fuel injected into the combustion chamber. Its precise engineering helps in optimizing fuel delivery, enhancing fuel efficiency, and ensuring smooth engine operation.

·

·

Injector Needle Valve (L250-52-101): The injector needle valve regulates fuel injection timing and volume, directly affecting engine performance. High-quality needle valves are essential for fuel economy and consistent engine power.

·

2. Air and Exhaust System: Maintaining Optimal Airflow

·

Air-Cooler Core (KLQ50H): An essential component for maintaining engine temperature, the air-cooler core dissipates heat from the air entering the engine. By reducing air temperature, it improves combustion efficiency and prolongs the engine's lifespan.

·

·

Exhaust Valve Seat (L250-H03-034) & Exhaust Valve (L250-03-031A): These parts ensure proper sealing and controlled release of exhaust gases. Durable and heat-resistant, they help maintain the correct pressure in the combustion chamber, which is critical for effective exhaust and intake cycles.

·

3. Fuel System: Ensuring Reliable Fuel Flow

·

Fuel Inlet Pipe (8L250-H50-600): This pipe delivers fuel to the injection system, and its integrity is essential for uninterrupted fuel flow. A robust fuel inlet pipe helps in maintaining consistent pressure, crucial for optimal combustion.

·

·

Fuel Pump (LB250): The fuel pump provides the necessary pressure to push fuel from the tank to the engine, ensuring smooth and efficient combustion. A reliable fuel pump is key to preventing fuel starvation and maintaining consistent engine power.

·

4. Gaskets and Seals: Preventing Leaks and Maintaining Pressure

·

Cylinder Head Shim (L250-01-045): Placed between the cylinder head and the engine block, this gasket prevents leaks and maintains optimal compression. Made from high-quality materials, it withstands extreme temperatures and pressures.

·

·

Various O-rings (e.g., L28-200012, GB3452.1 51.5x2.65 G): These O-rings serve as seals to prevent oil, fuel, or coolant leaks. They are crucial for maintaining the integrity of the engine's various fluid systems.

·

5. Piston Rings: Enhancing Engine Efficiency

· Piston Ring №1, №2, №3 (L250-05-021, L250-05-022, L250-05-023): These rings ensure a tight seal between the piston and the cylinder wall, which is essential for maintaining compression and preventing gas leakage. High-quality piston rings reduce oil consumption and improve engine efficiency.

6. Other Vital Components

·

Camshaft (L250-12-070A): This component controls the timing of intake and exhaust valves, influencing the engine's performance and efficiency. Precision-engineered camshafts ensure optimal engine operation and help maximize power output.

·

·

Centrifugal Water Pump (L250-71-000): This pump circulates coolant through the engine, preventing overheating. A reliable water pump is essential for temperature regulation and long engine life.

·

·

Safety Valve (L250-14-000): Designed to release excess pressure, the safety valve protects the engine from potential damage. It is an essential component for maintaining safe operating conditions in high-pressure environments.

·

Conclusion

Each component in an engine has a specific function that contributes to overall performance and reliability. By understanding the roles of these parts—from fuel injectors to exhaust valves—it's clear that investing in high-quality engine components is essential for maintaining optimal operation, safety, and longevity. Whether for industrial applications or high-performance engines, these components are the backbone of a powerful and reliable engine.