Welcome to Shandong Hongfan Power Technology Co.,Ltd

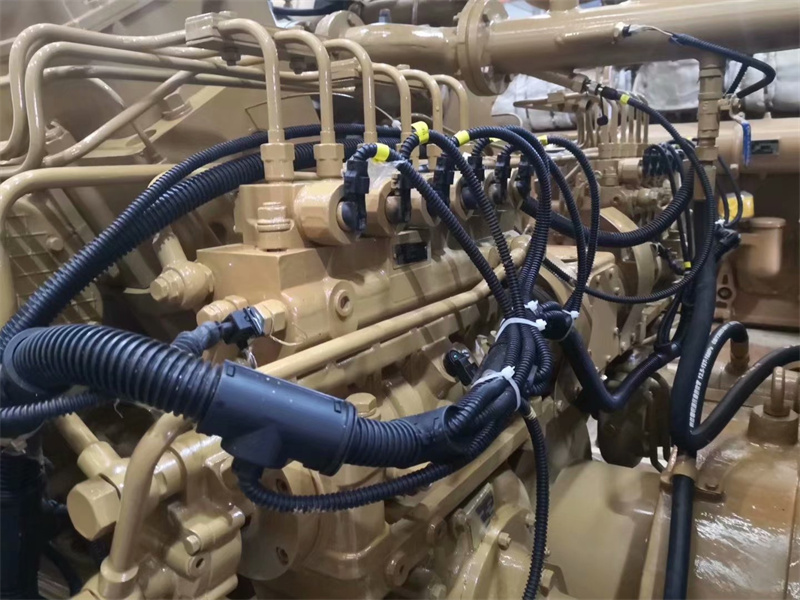

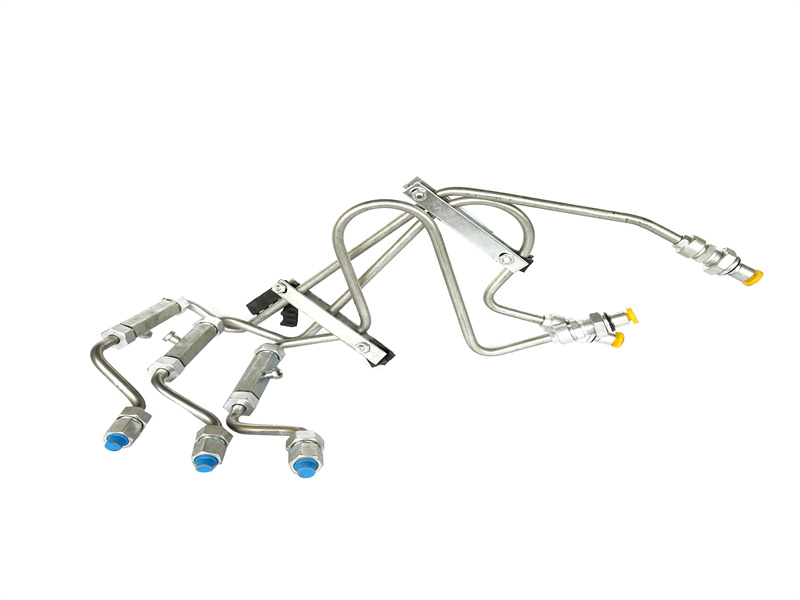

Jichai 190 parts 12VB.14.10 12VB.14.20 left/right high pressure oil pipe part

190 Parts Sales Center is a Jichai parts supplier. The company is located in Jinan, Shandong, and provides Jichai 190 engine and generator set parts to thousands of customers.

Jichai Parts Sales Center provides 24-hour customer service, consultation hotline 18766952912, parts warehouse, convenient logistics, fast delivery, original parts quality,

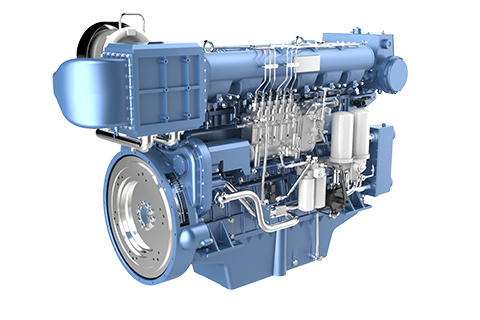

reasonable price! The company supplies Jichai 190 parts, Jichai diesel engine parts, Jichai 12V190 drilling matching diesel engine parts, Jichai 6190/8190 marine engine parts,

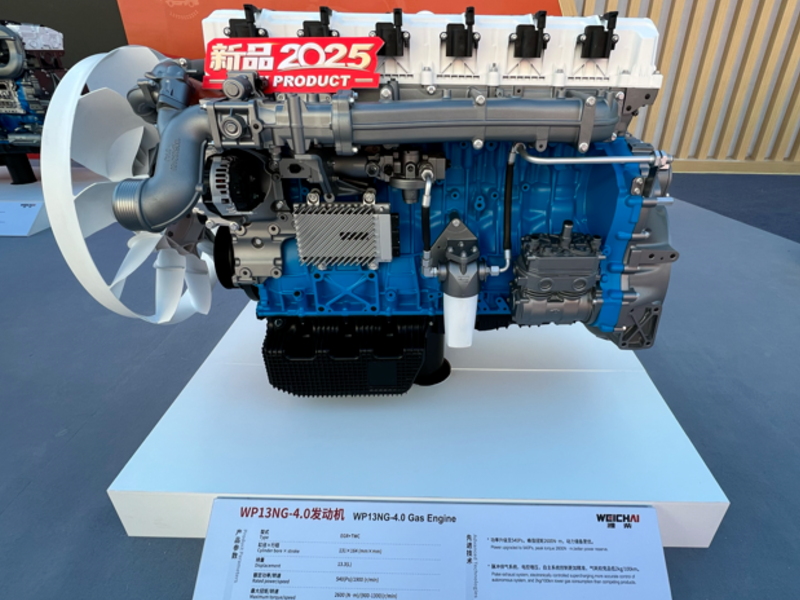

Jichai natural gas generator set parts, Jichai 500KW, 600KW biogas generator set parts, Jichai 500KW, 600KW, Jichai H16V190 gas engine parts, Shengdong 190 gas engine parts.

The main products of Jichai 190 are: 6190 accessories, 8190 accessories, 12V190 accessories, Jichai H16V190 accessories, gas engine accessories, biogas generator accessories,

gas engine accessories, and marine engine accessories. Supply 190 accessories, engine body, crankshaft, 12VB.03.00 diesel engine cylinder head assembly,

gas engine cylinder head assembly, 16V gas engine cylinder head assembly, 190 connecting rod assembly, connecting rod bearing, thrust bearing, thrust plate,

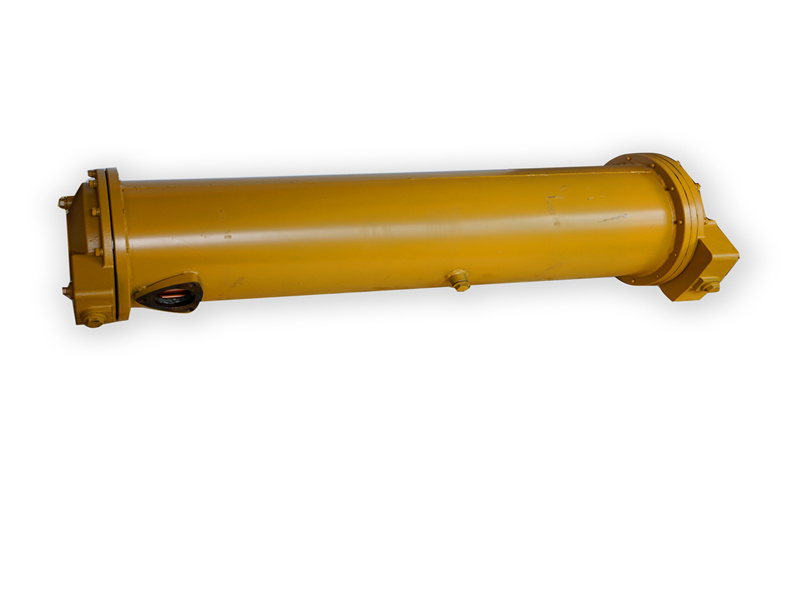

Z12VB.05.01C piston, 190 cylinder liner, supercharger (20GJ supercharger, SJ160 supercharger, J170 supercharger) intercooler, 12VB.22.00B water pump,

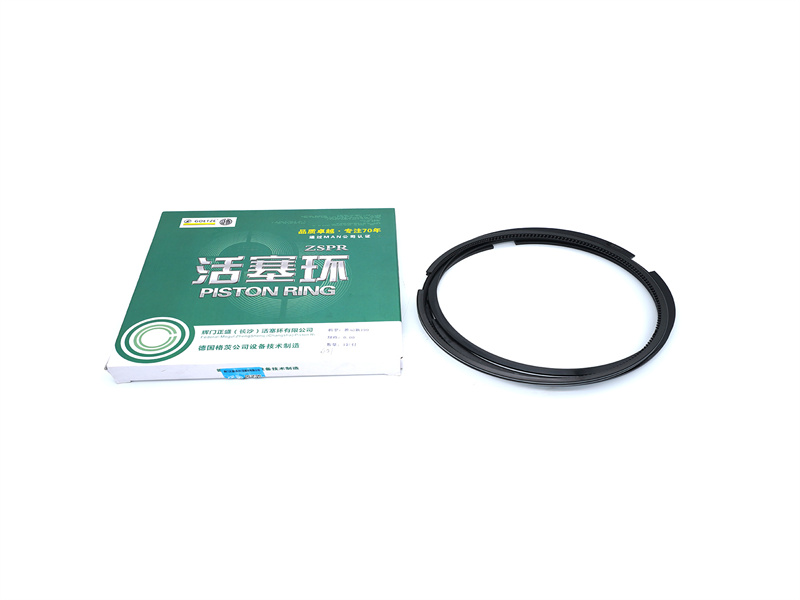

Jichai overhaul kit, full vehicle pad, 190 camshaft, air motor, electric starter motor, 3411 high elastic coupling, Changsha Zhengsheng piston ring set,

190 intake and exhaust valves and seat rings, three-core speed sensor , instrument panel, STITT spark plug, ignition coil, 127.90.10 high-voltage wire,

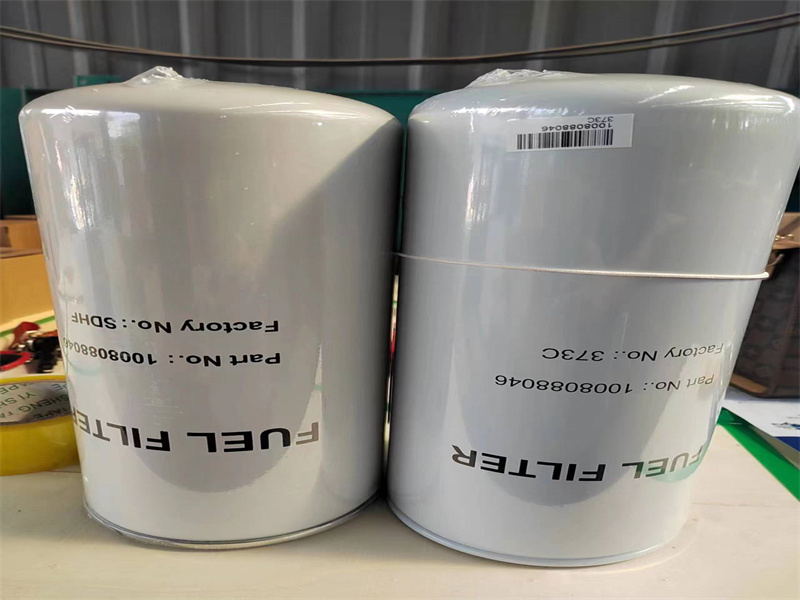

ignition controller, 190 oil filter, 190 accessories, 12VB.21.00 oil cooler, high-pressure oil pump, speed governor, centrifugal filter, Jichai oil filter, Jichai 12V190 accessories,

Jichai air filter, Jichai three filters, Jichai joint narrow V-belt, Jichai injector, Jichai ZCK150S835 injector pair, ZCK150S840 injector pair, 12V.29.00 hand-cranked oil pump,

307.54.00 electric pre-supply oil pump, seawater pump, Jichai coupler accessories.

12V190 maintenance tools, cylinder liner scraper, valve seat disassembly and assembly tools, valve guide disassembly and assembly tools, piston ring disassembly and

assembly tools, piston disassembly and assembly tools, valve seat reamer, torque wrench, 190 valve spring disassembly tools.

(II) Use and maintenance of Jichai injectors

1. Diesel of the specified brand must be selected and strictly filtered.

2. The diesel engine must not be idle for a long time to avoid carbon deposits and blockage of the spray holes due to poor combustion.

3. Clean the injector regularly and check the injection pressure and atomization conditions. Under normal circumstances, it should be cleaned and calibrated once every

250 hours of operation.

(III) Verification of injectors

1. The opening pressure of the injector needle valve is specified to be 19.6 ± 0.49 MPa.

2. Spray test: The injector sprays fuel at a frequency of 40 to 80 times per minute on the test bench, and observes the condition of the sprayed fuel. Under normal circumstances,

it should be uniformly misted. If abnormal phenomena occur, it should be disassembled and inspected in time.

3. Disassembly and inspection of the fuel injector

(1) Remove the fuel injector from the cylinder head. Note: The gasket under the original fuel injector cannot be replaced by mistake.

(2) Soak the removed fuel injector parts in clean gasoline (diesel) oil and clean them separately. Note: During the cleaning process, the parts should be kept paired and cannot

be replaced.

(3) Check whether the parts are damaged. If damaged, they must be replaced in groups. When installing the fuel injector cap, the tightening torque is specified to be 58.8-78.4N,m. After the fuel injector is installed in the cylinder head, the height of the fuel head protruding from the bottom of the cylinder head should be checked.

Good maintenance is an important guarantee for the normal and reliable operation of the diesel engine and the extension of its service life. The user should perform regular maintenance according to the following technical maintenance items. The specific maintenance requirements and cycles can be adjusted appropriately according to the use status and environmental conditions of the diesel engine.

(I) Daily maintenance

Each shift operator must carefully fill in the operation record of the shift, and record in detail the various parameters of its operating status, the faults found, and the measures taken. The following work should be completed:

Check the oil level in the fuel tank.

Check whether the oil level of the oil pan, injection pump, and governor is abnormally increased or decreased, and check the oil quality. Add oil if necessary.

Check the water level in the radiator tank, and add cooling water and antifreeze if necessary.

Check the air source pressure. When using an electric motor, check the battery charging status.

Wipe the surface of the diesel engine.

Check whether the instrument is normal.

Monitor whether the instrument is normal.

Observe the exhaust status of the diesel engine and listen to the sound of the diesel engine. If any abnormality is found, find the cause in time and eliminate it.

Check and eliminate the diesel engine oil, water, and air leakage, and keep the appearance and environment of the diesel engine neat and clean.

(II) Weekly maintenance

Complete all items specified in daily maintenance.

Check and clean the air filter (if the working environment is windy and sandy, the cleaning cycle can be shortened as needed), and clean the dust in the dust box.

Use an oil gun to spray oil on the injection pump's plunger spring, oil adjustment gear ring and gear rod to prevent rust.

Drain the water in the air pipe and oil-water separator.

Drain the water and sediment in the fuel tank.

(III) Monthly maintenance

Complete the items specified in daily and weekly maintenance.

Clean the fuel filter.

Check the oil filter inlet and oil pressure difference. If it is greater than 196kPa, the paper filter element should be replaced.

Check and adjust the tension of the fan belt.

Check the tightness of the diesel engine's connection and fixing parts.

Clean the centrifugal filter and the breather filter.

Add No. 3 graphite lithium-based grease to the injection pump transmission and connector, and add calcium-based grease to the Jichai pneumatic motor. Add oil to the oil mist device and pneumatic pre-supply pump

Check and adjust the injection pump's fuel supply advance angle.

Check the injection pressure of the injector, observe the atomization quality, and clean the injector or adjust the injection pressure.

Clean and check the main filter element and coarse filter of the air filter.

Verify the sensor of the alarm system.

Disassemble and clean the throttle control device, check whether the control device is flexible and reliable, and add grease.

Check whether the metal rubber seat of the elastic coupling has cracks, and replace the rubber seat if necessary.

After the new machine has run for 250 hours, the cylinder head bolts should be checked for tightness, and pay attention to check whether the exhaust pipe and cylinder head fixing bolts are loose and tight.