Welcome to Shandong Hongfan Power Technology Co.,Ltd

How to Maintaining the Fuel Injection Pump of the Chidong G12V190PZL-3 Engine

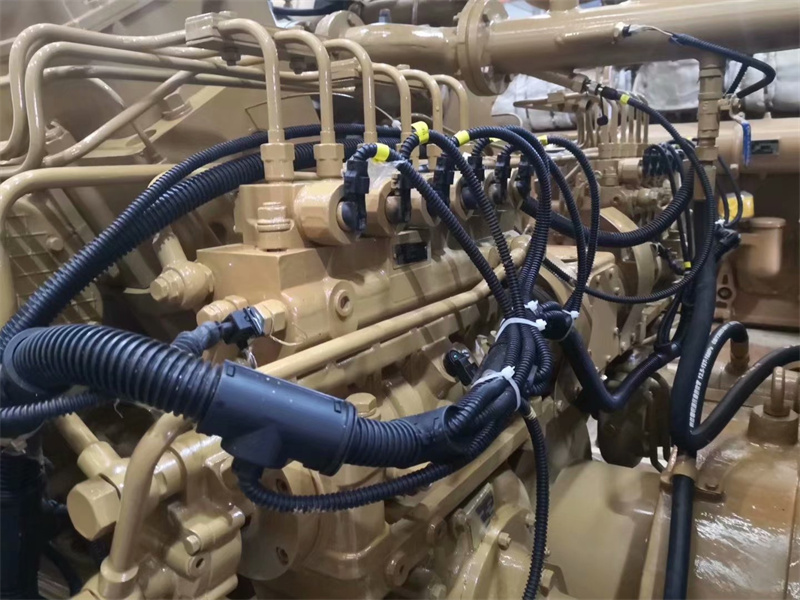

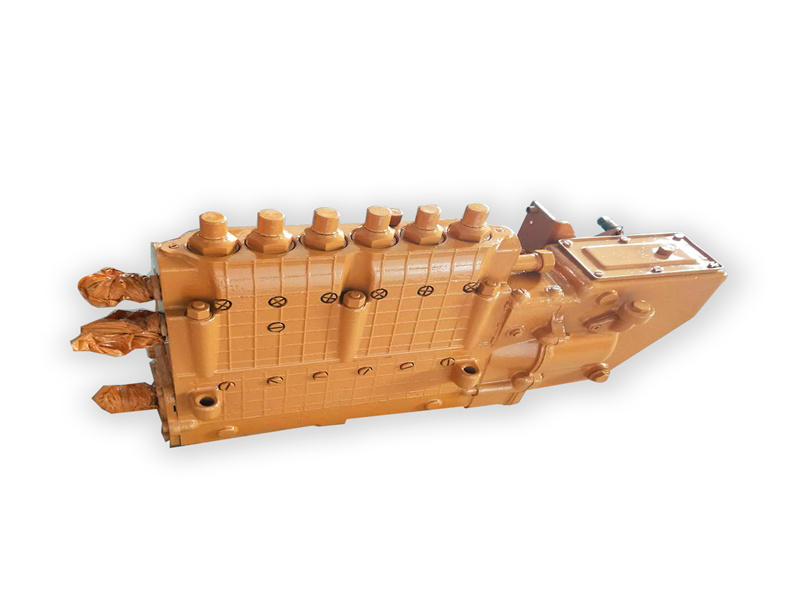

In the oil and gas drilling industry in Russia and Kazakhstan, the Chidong G12V190PZL series engines are highly favored for their cost-effectiveness and ease of maintenance. This article provides a detailed guide on the maintenance and servicing of the fuel injection pump (high-pressure fuel pump) with part numbers BH6Z140ZT or Z12V.12.00, helping users extend equipment lifespan and enhance operational efficiency.

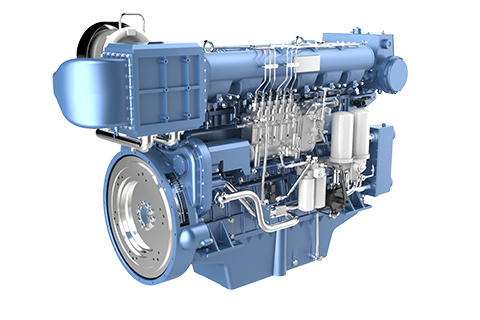

I. Core Specifications of the Jinan G12V190PZL-3 Engine

Power Output: 810 HP

Speed: 730/1300 RPM

Fuel Consumption: ≤209.4 g/kW (depending on load conditions)

Dimensions (L × W × H): 3860 × 2040 × 2678 mm

Net Weight: 8200 kg

II. Key Maintenance Points for the Independent Lubrication System of the Fuel Injection Pump

The fuel injection pump of the Chidong G12V190PZL-3 engine operates on an independent lubrication system, separate from the engine’s lubrication system. Therefore, the internal oil of the fuel injection pump must be changed regularly during engine operation. Over time, fuel can gradually seep into the fuel injection pump crankcase, diluting the lubricant and causing lubrication failure, which can result in severe malfunctions if not addressed promptly.

2.1 Standardized Oil Change Process

Use the same type of engine oil as in the engine.

Monitor discharged oil by connecting a transparent container to the overflow pipe.

Follow the scheduled maintenance intervals as per the operation manual (for older engines, reduce the interval by 30%).

III. Preventive Maintenance Strategies

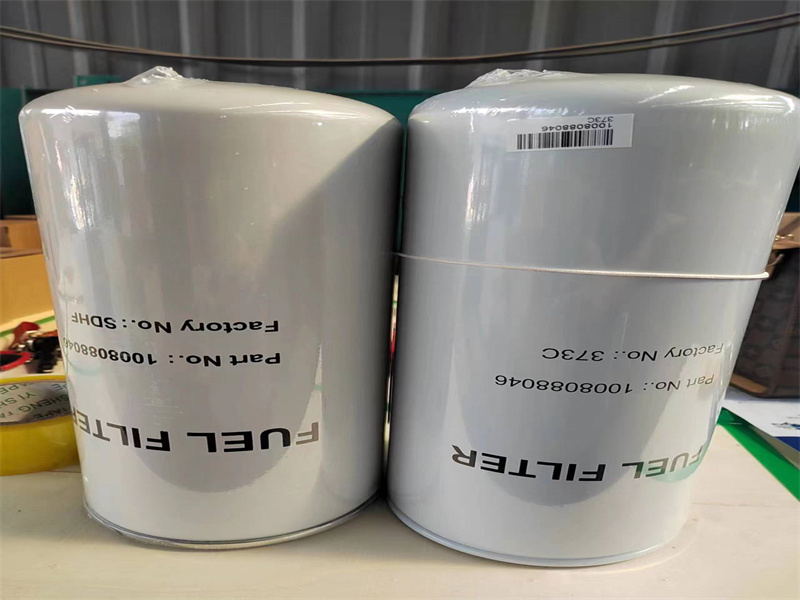

3.1 Filter Replacement

Change oil and fuel filters every 400 hours to maintain a clean fuel system.

3.2 Lubrication Monitoring

Continuously monitor crankcase oil quality to prevent dilution.

3.3 Regular Calibration

Perform valve timing recalibration every quarter to ensure proper engine operation.

3.4 Overhaul Cycle

After 20,000 hours of cumulative operation, a comprehensive overhaul is recommended.

IV. Technical Tips

Abnormal discharge from the overflow pipe can directly indicate plunger assembly wear, so regular inspections are advised.

Routine fuel injection pump maintenance can significantly improve engine stability and reduce repair costs.

The Chidong G12V190PZL-3 engine is widely recognized for its cost-effectivenss and ease of maintenance. By following this fuel injection pump maintenance guide, you can significantly extend equipment lifespan and improve operational efficiency.

If you needs any parts of jinan diesel engine, contact us [email protected]