Welcome to Shandong Hongfan Power Technology Co.,Ltd

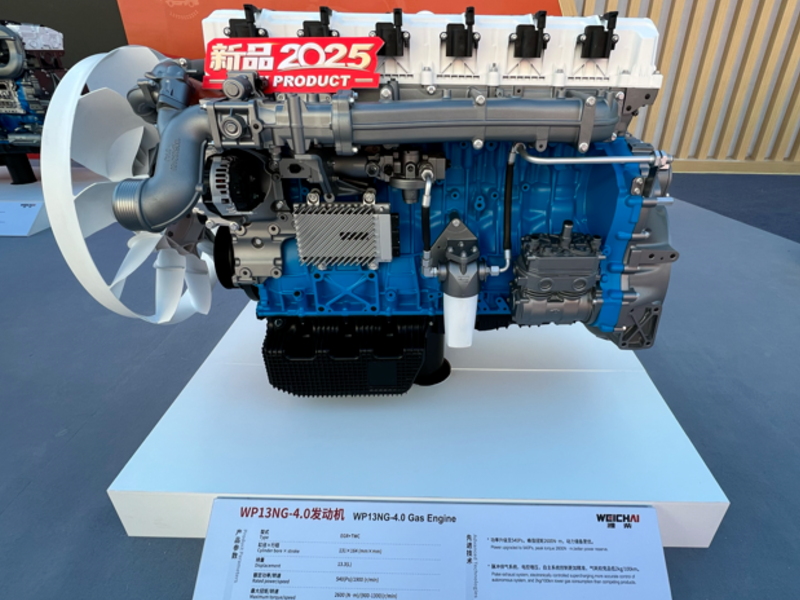

LNG Gas System Usage and Maintenance Guide-taking Weichai Brand as an Example

Proper Use and Maintenance of LNG Gas Systems: A Comprehensive Guide

With the increasing use of Liquefied Natural Gas (LNG) in vehicles, ensuring the correct use and maintenance of LNG gas systems has become a priority for vehicle owners and fleet operators. This article provides a detailed guide on daily inspections, maintenance, leak detection, component replacement, acceptance and storage, refueling precautions, driving operation standards, and common troubleshooting methods to help ensure vehicle safety.

I. Daily Inspection and Maintenance

1. Routine Maintenance Requirements

Routine maintenance of LNG gas systems is key to ensuring vehicle safety. Below are the common maintenance tasks and their intervals:

Connection nuts of cylinders and brackets: Check and tighten every 15 days.

Pipeline connection nuts of cylinders: Visually inspect for leaks before each trip.

Vaporizer: Clean scale deposits on coils every 6 months.

Valves: Regularly check for improper closure or leaks.

Safety valves and pressure gauges: Calibrate annually at the local technical supervision department.

Cylinder vacuum level: Perform pressure tests every 12 months.

Self-pressurizer: Regularly clean dirt off fins.

Tighten cylinder straps: Frequently check and tighten nuts.

2. Leak Detection

Regularly use a portable methane detector to check for gas leaks. If a leak is detected, repairs should be performed immediately. If the leak source is unclear, soap water can be used for auxiliary detection.

3. Component Replacement

Threaded pipe leaks: Disassemble, clean the connection surface, and seal with Teflon tape.

Pipe fittings leaks: Inspect by disassembly; if undamaged, reinstall and tighten.

Valve leaks: Return to the cylinder manufacturer for repair or replacement.

Safety valve: Calibrate annually; unauthorized repairs or adjustments are strictly prohibited.

4. Vacuum Failure

Vacuum failure usually manifests as frost formation on the cylinder or a rapid pressure increase. If vacuum failure occurs, the cylinder should be returned to the manufacturer for repair. Such cylinders must undergo a specialized re-vacuuming process.

II. Acceptance and Storage

1. Acceptance Inspection

Carefully verify that the received product matches the order. Check if the factory documents are complete, consistent, correct, and valid. Inspect the cylinder pressure, safety accessories, instruments, valve condition, and whether the safety valve seal is intact.

2. Long-Term Parking

When a vehicle is parked for an extended period, cylinders should be stored away from corrosive environments and maintained under dry nitrogen-sealed pressure. It is strictly forbidden to open any valves to release internal pressure. Safety valve seals must remain intact unless exceeding the inspection cycle.

III. Refueling Precautions

1. Environmental Requirements

During refueling, no open flames or flammable materials should be within a 50-meter radius. The site should be spacious, well-ventilated, and equipped with dry powder fire extinguishers and a water source.

2. Vehicle Condition

The vehicle should be turned off, and all cylinder valves should be closed during refueling. The filling port should be kept clean and free from moisture. Before refueling, check for condensation or frost on the cylinder’s exterior—if present, do not proceed with refueling.

3. Preventive Measures

Operators should wear protective goggles, face shields, insulated gloves, and protective clothing to prevent liquid splashes. If a valve is frosted, do not force it open; use warm water to defrost before operating.

IV. Driving Operation Standards

1. Startup Procedure

When starting the vehicle, slowly open the liquid cutoff valve. Once the gas circuit pressure equals the cylinder pressure, fully open the valve. If the ambient temperature is below 0°C, preheat the engine until the coolant reaches at least 60°C before driving.

2. Liquid Level Alarm

If the liquid level alarm is activated, refill the LNG immediately to prevent vehicle stalling. Always maintain a residual level of 1-5L in the tank to ensure positive pressure.

V. Common Faults and Troubleshooting

1. Vaporizer Frosting

Frost on the vaporizer surface may indicate low coolant temperature. Stop the vehicle and preheat until the coolant reaches 60°C before driving.

2. Safety Valve Activation

A safety valve may activate due to excessive pressure or malfunction. Replace the safety valve according to operational procedures.

3. Cylinder Tilting

A tilted cylinder may cause an overfill valve blockage. Loosen the straps, reposition the cylinder, and then re-secure it.

VI. Gas Supply System and Cylinder Documentation

The accompanying vehicle documents should include equipment installation, maintenance, usage, and servicing manuals, packing lists, product certificates, and manufacturing licenses.

VII. Basic Injury Treatment Methods

1. Cold Burns

If skin adheres to a low-temperature surface, warm water should be used to thaw and detach it, and the injured person should be moved to a warm location. Frostbitten areas should be treated with a water bath at 40-45°C.

2. Leak Handling

Ensure ventilation in the leak area and install combustible gas detectors. To extinguish LNG fires, use chemical dry powder extinguishers—do not use water.

3. Asphyxiation Response

If personnel lose consciousness due to oxygen deficiency, remove them from the area immediately and perform artificial respiration. Maintain ventilation to keep oxygen concentration above 19%.

Conclusion

Proper use and maintenance of LNG gas systems are essential for vehicle safety. Regular inspections, maintenance, and standardized operations can effectively prevent failures and accidents, extending the service life of equipment. This guide aims to provide practical instructions to ensure the safe and efficient operation of LNG vehicles.