Welcome to Shandong Hongfan Power Technology Co.,Ltd

How to adjust Gas Engine Valve Clearance? Taking Jichai 500KW 12V190 as an example.

1. Overview

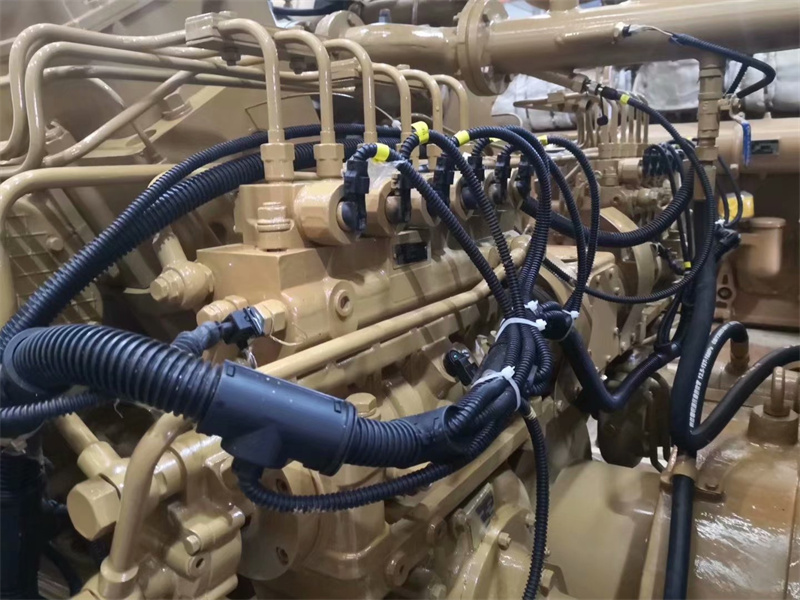

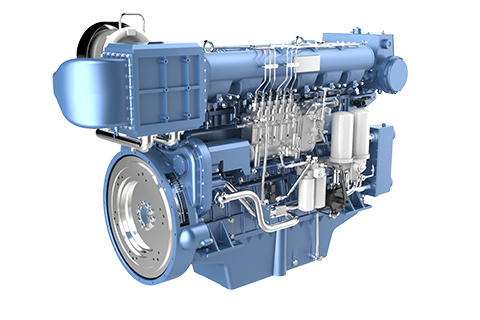

Valve clearance adjustment is a crucial step to ensure the efficient operation of a gas engine. Accurate valve timing adjustments can improve fuel efficiency, reduce wear, and extend the engine's lifespan. This guide details the valve clearance adjustment method for the Jichai 500GF-TK G12V190ZLDT gas engine in a cold engine state. This method is also applicable to the Shengdong 500KW gas engine.

2. Valve Timing Adjustment Guidelines

2.1 Cold Engine Adjustment Specifications

In the cold engine state, the recommended valve clearance adjustment values are as follows:

Intake Valve Clearance: 0.43mm (allowable error ±0.03mm)

Exhaust Valve Clearance: 0.48mm (allowable error ±0.03mm)

2.2 Valve Timing Adjustment Method

Before adjusting, the engine must be set to cylinder 1 or cylinder 6 at the 0° position, referencing the factory scale marks on the flywheel (range 0°–360°). The flywheel is equipped with a fixed pointer on the starter side (do not move or bend it, as it is factory adjusted). Adjust the engine according to the following flywheel angle positions:

| Flywheel Angle | Corresponding Cylinder |

|---|---|

| 0° | Cylinder 1 |

| 60° | Cylinder 8 |

| 120° | Cylinder 5 |

| 180° | Cylinder 10 |

| 240° | Cylinder 3 |

| 300° | Cylinder 7 |

| 0° | Cylinder 6 |

| 60° | Cylinder 11 |

| 120° | Cylinder 2 |

| 180° | Cylinder 9 |

| 240° | Cylinder 4 |

| 300° | Cylinder 12 |

Cylinder Layout:

Left Bank (from starter to radiator): Cylinders 1-6

Right Bank (from flywheel to radiator): Cylinders 7-12

2.3 Valve Clearance Adjustment Steps

Pre-adjust the balancer: Use the adjustment screw to ensure the balancer evenly contacts both valves.

Feeler gauge check: Adjust the rocker arm clearance to the recommended value and ensure accuracy.

Dynamic verification: Start the engine and check the lubrication oil supply.

Final inspection and sealing: After confirming the adjustment is correct, install and seal the valve cover.

3. Cylinder Head Disassembly and Assembly Guidelines

Proper disassembly and assembly of the cylinder head helps prevent deformation and leakage, improving maintenance efficiency.

3.1 Cylinder Head Disassembly and Assembly Steps

Use a 360 N·m torque wrench to ensure uniform force application.

Apply a cross-pattern progressive tightening method to prevent uneven stress on the cylinder head.

Three-stage incremental tightening:

Step 1: 120 N·m

Step 2: 240 N·m

Step 3: 360 N·m

4. Preventive Maintenance Strategy

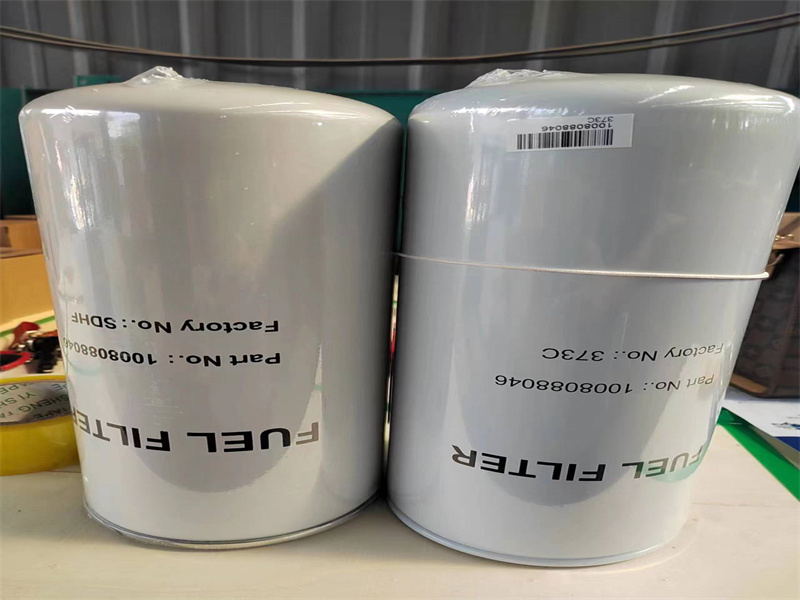

Filter replacement: Replace the oil/fuel filter every 400 hours to keep the fuel system clean.

Lubrication monitoring: Monitor the quality of the crankcase oil in real time to avoid wear caused by poor lubrication.

Periodic calibration: Perform a valve timing recheck every quarter to ensure normal engine operation.

Overhaul cycle: It is recommended to conduct a comprehensive overhaul after 20,000 hours of accumulated operation to restore optimal performance.

5. Conclusion

By strictly following the above adjustment steps, the performance and reliability of the Jichai 500GF-TK G12V190ZLDT gas engine can be significantly improved, reducing the likelihood of failure. Regular maintenance and precise valve clearance adjustment will ensure long-term stable operation of the engine, improve fuel efficiency, and lower operating costs.