Welcome to Shandong Hongfan Power Technology Co.,Ltd

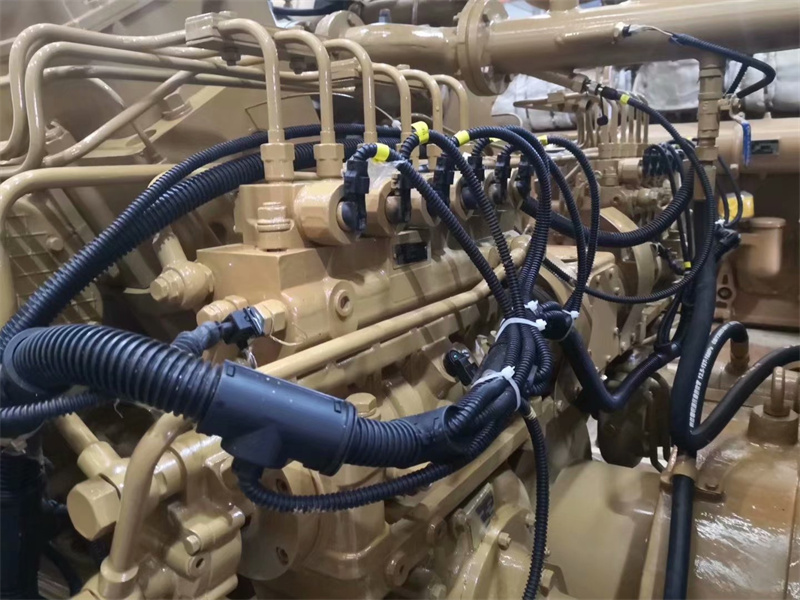

127.13D.03 MP4 speed sensor used in 12V190 20V190 gas generator

Engine Fails to Start

When an engine won't start, it's typically due to electrical, ignition, or fuel supply issues. Here are the most common causes and how to fix them:

Common Causes and Solutions:

Faulty or Loose Cables

Inspect all cables and connectors. Repair or replace as necessary.

Defective Ignition Switch

Replace the ignition switch if it's unresponsive or damaged.

Insufficient Fuel Gas Supply

Check the natural gas valves, solenoid valves, and actuators to ensure proper fuel flow.

No Spark at the Spark Plug

Inspect both high- and low-voltage cables. Replace damp or damaged ignition coils. Clean or replace spark plugs if fouled with carbon. Adjust the spark gap and inspect the ignition signal sensor.

Fuel Gas Contaminated with Air or Water

Ensure the gas supply is clean and dry. Drain or filter as needed.

Low Starting Speed

Examine the starter motor and battery. Replace or recharge as necessary.

EGS System Not Operating

Diagnose and service the Engine Gas System (EGS).

Uneven Engine Operation

Engines that run erratically or with inconsistent speed may suffer from ignition issues, incorrect settings, or sensor problems.

Common Causes and Solutions:

Malfunctioning Ignition System

Conduct a comprehensive check of all ignition components and cable connections.

Low Natural Gas Line Pressure

Check for leaks and inspect the pressure regulator diaphragm. Ensure shared gas lines deliver adequate pressure.

Incorrect A/F or PID Speed Adjustment

Compare current Air/Fuel and PID speed settings with historical data. Adjust as needed.

Mechanical Engine Failure

Check for air leaks or wear in turbochargers and air intake systems.

Faulty Speed Sensor

Inspect wiring and magnetic sensors. Compare voltage and waveform signals.

Actuator or Linkage Issues

Exit “Test Mode” and inspect actuator linkages during engine shutdown. Recalibrate the speed controller and ensure smooth linkage operation.

Inappropriate Power Signal Filtering Settings

Reset filtering time between 0.01 to 0.2 seconds. Navigate to: Parameter → Sensor → Measure Power.

Damaged Controller

Inspect the controller unit. Repair or replace as needed.

Valve Clearance or Leakage Issues

Readjust valve clearances and reseat valves to prevent air leaks.

Engine RPM Too Low or Stalling

Low RPM or engine stalling can often be attributed to load and fuel delivery problems.

Common Causes and Solutions:

Excessive Load

Check all accessories powered by the engine. Reduce the overall load if necessary.

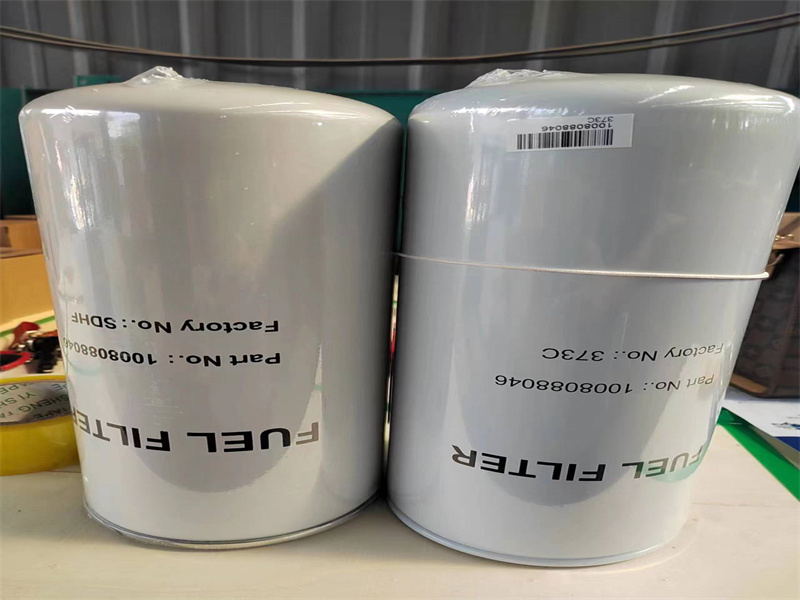

Insufficient Fuel Supply

Inspect turbochargers and fuel lines. Ensure there's no blockage or leak reducing gas flow.